SmartSeal is a commercial roofing expert and in this article, our aim is to provide a comparative analysis of water-based coatings and solvent-based coatings. As the demand for environmentally friendly and compliant coatings increases, many industries are considering the switch from traditional solvent-based coatings to water-based alternatives. In this article, we will explore the pros and cons of both options, helping you make an informed decision that aligns with your project requirements and environmental considerations.

Key Takeaways:

- Water-based coatings have lower VOC emissions and are more environmentally friendly.

- Solvent-based coatings offer faster curing times and a higher sheen finish.

- Water-based coatings have excellent adhesion and color retention, while solvent-based coatings may become brittle with age.

- Water-based coatings are commonly used in industries such as fuel storage and railroad tank cars.

- Solvent-based coatings find applications in automotive, aerospace, marine, and construction industries.

Advantages of Water-Based Coatings

Water-based coatings offer several key advantages that make them a preferred choice in many applications. These coatings have properties that not only benefit the environment but also provide practical advantages for users.

1. Reduced VOC Emissions: Water-based coatings emit fewer Volatile Organic Compounds (VOCs), making them safer for workers and the environment. This is particularly important in industries where strict regulations govern VOC emissions.

2. Low Odor: Unlike solvent-based coatings that often have a strong smell, water-based coatings have minimal odor. This creates a more pleasant working environment while also enhancing the overall air quality.

3. Less Flammable: Water-based coatings have a lower flammability compared to solvent-based coatings. This significantly reduces the risk of fire during application and storage.

4. Reduced Disposal Fees: Since water-based coatings are environmentally friendly, they can help reduce disposal fees. Unlike solvent-based coatings, water-based coatings are not classified as hazardous waste, leading to cost savings in waste management.

5. Easy Cleanup: Water-based coatings can be easily cleaned up with water, eliminating the need for harsh solvents or additives. This simplifies the cleaning process while also reducing the consumption of additional materials, ultimately saving time and money.

6. Excellent Adhesion and Color Retention: Water-based coatings exhibit excellent adhesion to various surfaces, ensuring a durable finish that lasts. Additionally, these coatings retain their color for a longer period compared to solvent-based coatings, maintaining a vibrant appearance over time.

Advantages of Solvent-Based Coatings

When it comes to coating options, solvent-based coatings have long been favored for their exceptional performance properties. These coatings offer a range of advantages that make them a popular choice for various applications.

One of the key advantages of solvent-based coatings is their fast curing time. They dry quickly, allowing for reduced downtime and faster project completion. This is particularly beneficial in industries where time is of the essence, such as automotive and manufacturing.

| Advantages of Solvent-Based Coatings |

|---|

| Fast curing time |

| Tolerance to adverse weather conditions |

| High sheen and tough finish |

| Potential brittleness with age |

Environmental Impact of Water-Based Coatings

Water-based coatings have a significant advantage over solvent-based coatings when it comes to environmental impact. Unlike solvent-based coatings, water-based coatings emit fewer volatile organic compounds (VOCs), which are harmful to both human health and the environment. The reduction of VOC emissions is crucial for complying with government regulations and contributing to cleaner air quality.

By choosing water-based coatings, companies can actively reduce their VOC output and minimize their environmental footprint. This not only benefits the planet but also helps businesses avoid fines for exceeding VOC quotas. The use of water-based coatings is a responsible and sustainable strategy that aligns with the growing demand for eco-friendly solutions.

Differences in Performance Between Water-Based and Solvent-Based Coatings

When it comes to performance, water-based and solvent-based coatings have distinct differences that make them suitable for different situations. Understanding these differences can help you make an informed decision about which type of coating is best for your project.

Water-based coatings are known for their resistance to environmental conditions during the curing phase. This means that fluctuations in temperature and humidity are less likely to affect the drying process, resulting in a more consistent finish. However, water-based coatings may require more careful surface preparation and may not be ideal for humid climates where extended drying times can be a challenge.

On the other hand, solvent-based coatings have the advantage of faster curing times. This can be particularly beneficial for projects with tight timelines or when there is a need for quick turnaround. Additionally, solvent-based coatings often have a higher sheen and a tougher finish, making them more resistant to wear and tear. However, it is important to note that over time, solvent-based coatings can become brittle, potentially impacting their durability and longevity.

To summarize the performance differences:

| Water-based Coatings | Solvent-based Coatings | |

|---|---|---|

| Drying Times | Longer | Shorter |

| Resistance to Environmental Conditions | Higher | Lower |

| Sheen and Finish | Less pronounced | Higher sheen, tougher finish |

| Durability | Good | Potentially brittle with age |

By understanding these performance differences, you can choose the appropriate type of coating that aligns with the specific requirements of your project, whether it’s prioritizing environmental considerations, quick drying times, or the desired sheen and finish.

Common Uses for Water-Based Coatings

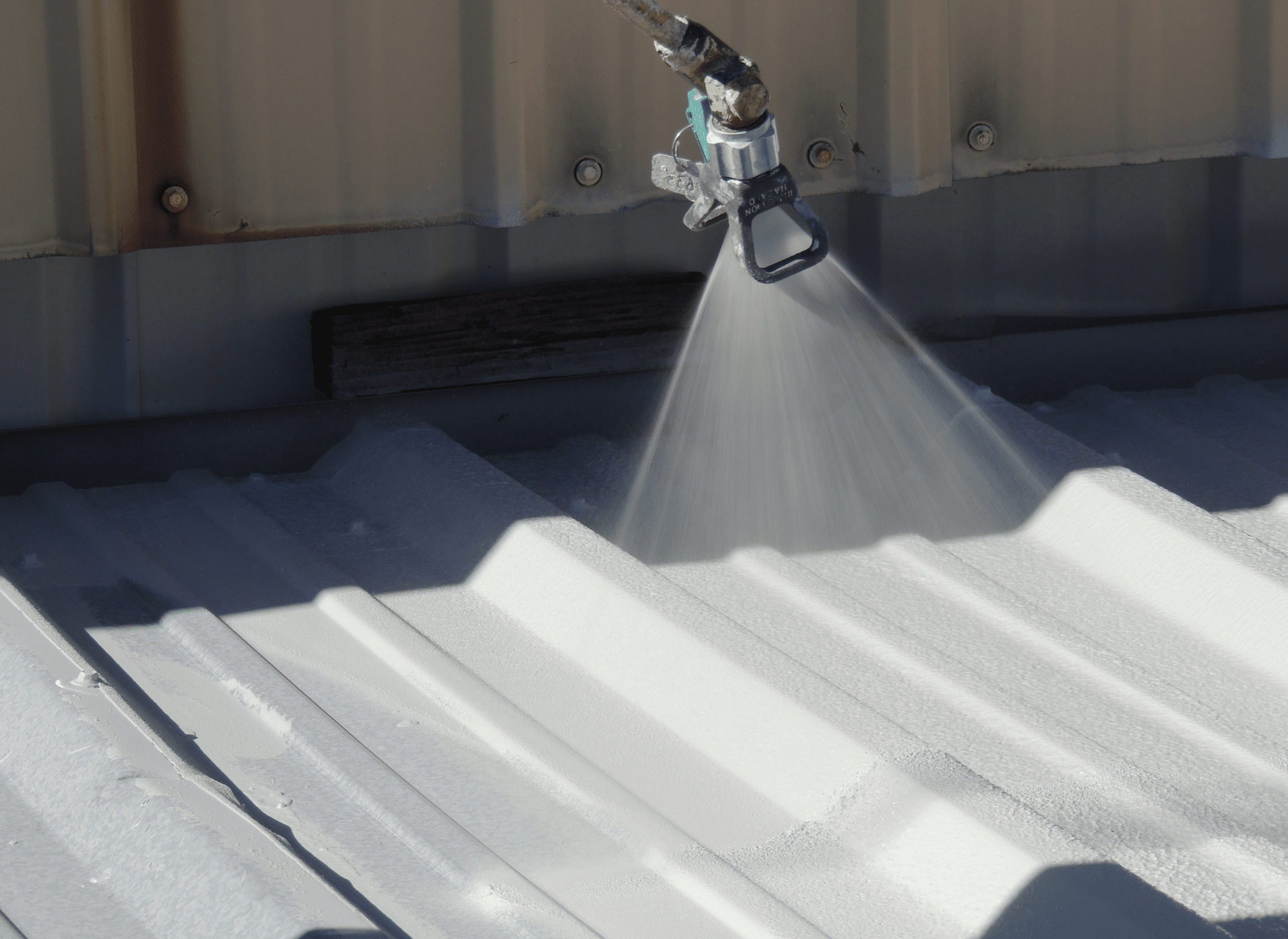

Water-based coatings are highly versatile and widely used in various industries for a range of applications. These coatings offer numerous benefits and are particularly suitable for projects that require protective and industrial coatings.

One common application of water-based coatings is for interior projects. Whether it’s painting walls, ceilings, or furniture, water-based coatings provide excellent adhesion and durability, ensuring long-lasting results. Their low odor and quick drying time also make them ideal for interior applications where minimal disruption is desired.

Water-based coatings are also preferred for heavy-duty protective needs. Industries such as fuel storage, railroad tank cars, and infrastructure recoating rely on these coatings to provide a reliable barrier against corrosion, chemicals, and harsh environmental conditions. Their ability to resist wear and tear, while maintaining the integrity of the underlying substrate, makes water-based coatings an excellent choice for heavy-duty protection.

By opting for water-based coatings, companies can not only achieve the desired protective and industrial outcomes but also contribute to environmental sustainability. These coatings help reduce the concentration of flammable materials, making them safer for workplaces. Additionally, they comply with stringent environmental regulations by significantly reducing VOC emissions, protecting both worker health and the environment.

| Common Uses for Water-Based Coatings | Benefits |

|---|---|

| Interior applications | Excellent adhesion and durability |

| Heavy-duty protective needs | Resistance against corrosion and harsh conditions |

| Projects involving confined spaces | Low VOC emissions for worker safety |

Common Uses for Solvent-Based Coatings

Solvent-based coatings are widely utilized in various industries, including automotive, aerospace, marine, and construction. These coatings are known for their exceptional performance properties and durability, making them a popular choice for a range of applications. They are particularly favored in projects that require a higher sheen and a tough finish, providing excellent protection and aesthetics. With their ability to withstand adverse weather conditions, solvent-based coatings are suitable for outdoor applications where durability is crucial.

Within the automotive industry, solvent-based coatings are extensively used for automotive refinishing, ensuring a flawless and long-lasting finish. In the aerospace sector, these coatings are applied to aircraft exteriors and components, offering protection against harsh environmental factors and adding to the visual appeal. Marine applications involve the use of solvent-based coatings on ships, boats, and other maritime structures, safeguarding against corrosion and marine growth. In the construction industry, solvent-based coatings are employed for protective purposes on metal structures, architectural elements, and concrete surfaces.

The versatility of solvent-based coatings extends to their use in industrial settings. They are commonly utilizzed as protective coatings for machinery, equipment, and various metal surfaces due to their resistance to abrasion, chemicals, and solvents. Solvent-based coatings also find application in the manufacturing of electrical components and appliances, providing insulation, moisture resistance, and durability. In addition, they are used in the oil and gas industry for corrosion protection on pipelines, storage tanks, and other infrastructure.

Conclusion

After conducting a comparative analysis of water-based and solvent-based coatings, we can conclude that each option has its own set of advantages and disadvantages. When making a decision, it is crucial to consider factors such as environmental impact, performance properties, and specific project requirements.

Water-based coatings offer significant benefits, including lower VOC emissions and compliance with environmental regulations. They are a more environmentally friendly choice, emitting fewer harmful substances into the air. These coatings also have the advantage of low odor and easy cleanup, making them more convenient to work with. However, they may have longer drying times and lesser sheen retention compared to solvent-based coatings.

On the other hand, solvent-based coatings have a well-established reputation for their performance properties. They cure faster and provide a higher sheen and tougher finish. These coatings are commonly used in industries such as automotive, aerospace, marine, and construction, where durability and resilience are crucial. However, they emit higher levels of VOCs, which can be harmful to human health and contribute to air pollution. Additionally, they are prone to becoming brittle with age.

Contact Kissimmee’s top commercial roof coating experts today to find out how our commercial roof coatings can help your building’s roof.

FAQs

What are the main differences between water-based and solvent-based coatings?

Water-based coatings have a lower environmental impact and emit fewer volatile organic compounds (VOCs) compared to solvent-based coatings. Solvent-based coatings, however, are known for their performance properties and durability.

What are the advantages of water-based coatings?

Water-based coatings have several advantages including lower VOC emissions, low odor, easy cleanup, and excellent adhesion. They are also safer for workers and the environment.

What are the advantages of solvent-based coatings?

Solvent-based coatings cure faster, have a higher sheen, and a tougher finish. They are commonly used in industries such as automotive, aerospace, marine, and construction for their performance properties and durability.

What is the environmental impact of water-based coatings?

Water-based coatings have a lower environmental impact as they emit fewer VOCs. This makes them safer for human health and helps companies comply with government regulations regarding VOC emissions.

How do water-based and solvent-based coatings differ in terms of performance?

Water-based coatings are less susceptible to environmental conditions during the curing phase, while solvent-based coatings cure faster. Water-based coatings may be challenging during surface preparation and are less suitable for humid climates.

What are the common uses for water-based coatings?

Water-based coatings are commonly used for interior applications, heavy-duty protective needs, and projects involving confined spaces. They are often used in industries such as fuel storage, railroad tank cars, and infrastructure recoating.

What are the common uses for solvent-based coatings?

Solvent-based coatings have a wide range of applications in industries such as automotive, aerospace, marine, and construction. They are commonly used for their performance properties and durability in outdoor applications.

What are the pros and cons of water-based and solvent-based coatings?

Water-based coatings offer lower VOC emissions, low odor, and easier cleanup. However, they may have longer drying times and less sheen retention compared to solvent-based coatings. Solvent-based coatings, on the other hand, cure faster, have a higher sheen, and a tougher finish. However, they emit more VOCs and can become brittle with age.

What should I consider when choosing between water-based and solvent-based coatings?

When choosing between water-based and solvent-based coatings, it is important to consider factors such as environmental impact, performance properties, and specific project requirements. The choice should be based on the desired outcome and environmental considerations.